Innovative Manufacturing Improvements

Comprehensive solutions to help you Revolutionize Your Process

The Ultimate Manufacturing expertise company

Rhino Tool House helps leading manufacturing companies across North America with products, software, custom engineered solutions, and personalized consultation. Our highly trained application engineers empower you to be more productive, build a better-quality product, and maintain a safe work environment.

Your Priorities are

Our Priorities

Your Productivity

Build it better, faster with optimized tools & systems

Your Quality

Bring consistency to your processes with technology

Your Safety

Eliminate risks & create ease for your employees

Solutions & Services Throughout Your Entire Organization

Where other companies claim to want to help you by selling you tools, Rhino Tool House works with you to help analyze your current situation and find better solutions to improve the effectiveness and efficiency of your manufacturing operations.

If you simply want a new or replacement tool, we’ve got that too. In fact, Rhino works hard to make sure we partner with the world’s leading tool manufacturers so that when you turn to Rhino, you’ve turned to the company who has not only the broadest selection of tools there is, but we also have the latest technologies focused on improving your productivity. We even have our own manufacturing resources to round out our entire line.

Let us work with you to analyze your current situation and find better solutions to improve the effectiveness and efficiency of you manufacturing or service operations. Let us help you achieve greater productivity today. Let us help you Revolutionize Your Process.

- Production Assembly Tools

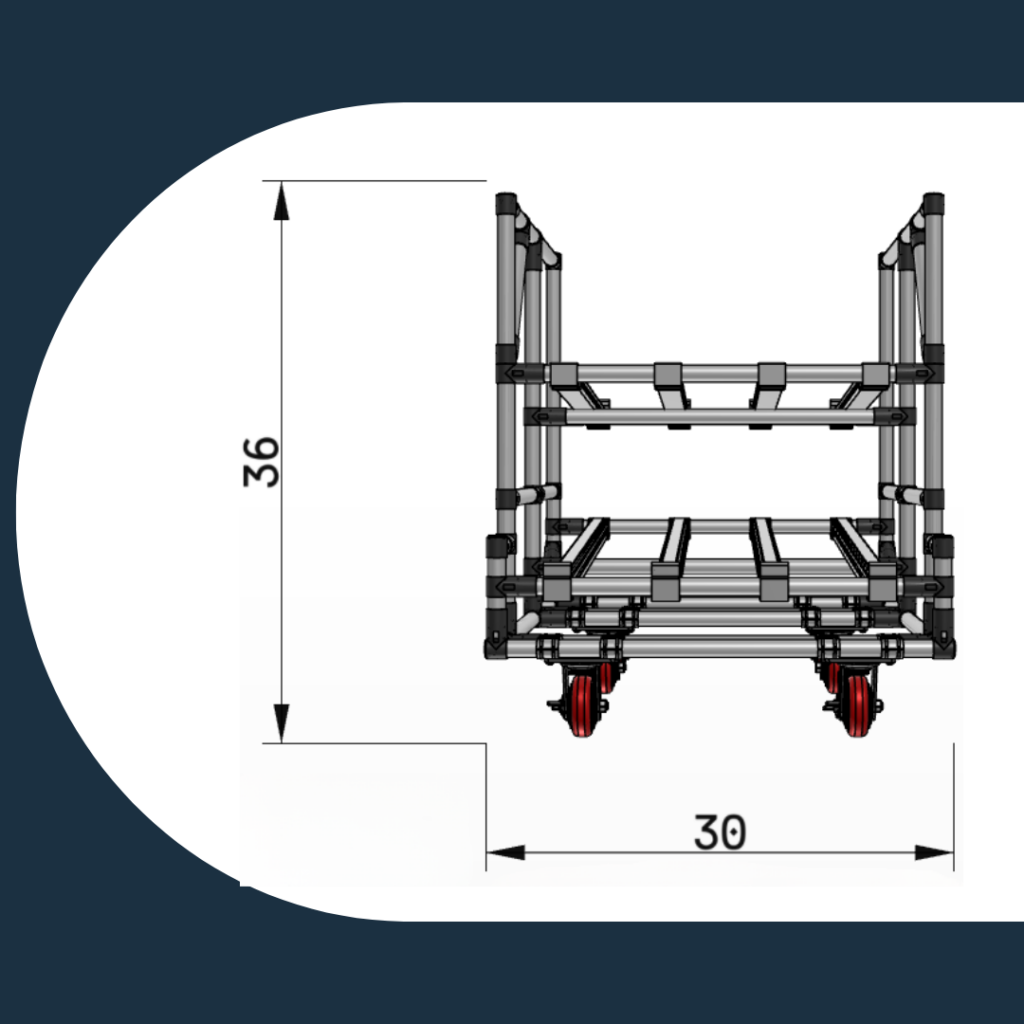

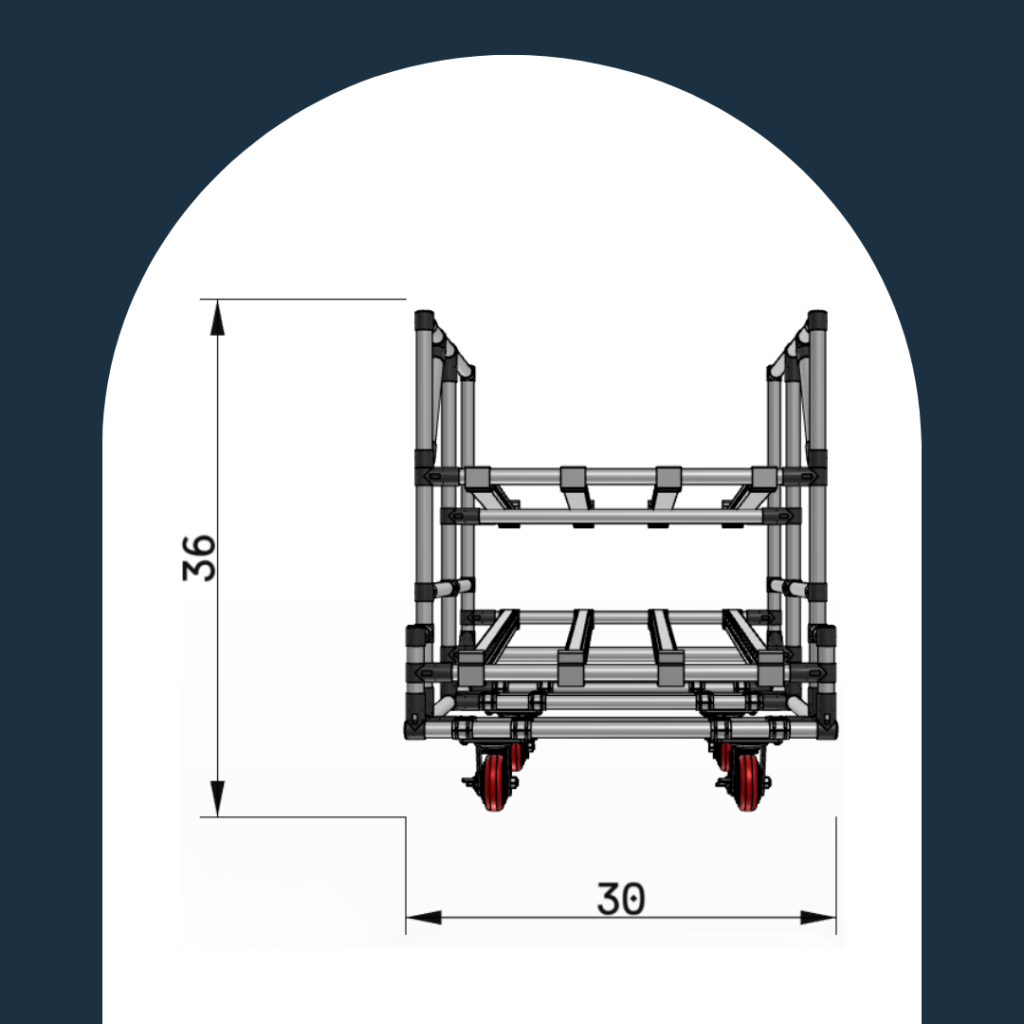

- Material Handling

- Workstations & Line-Side Delivery

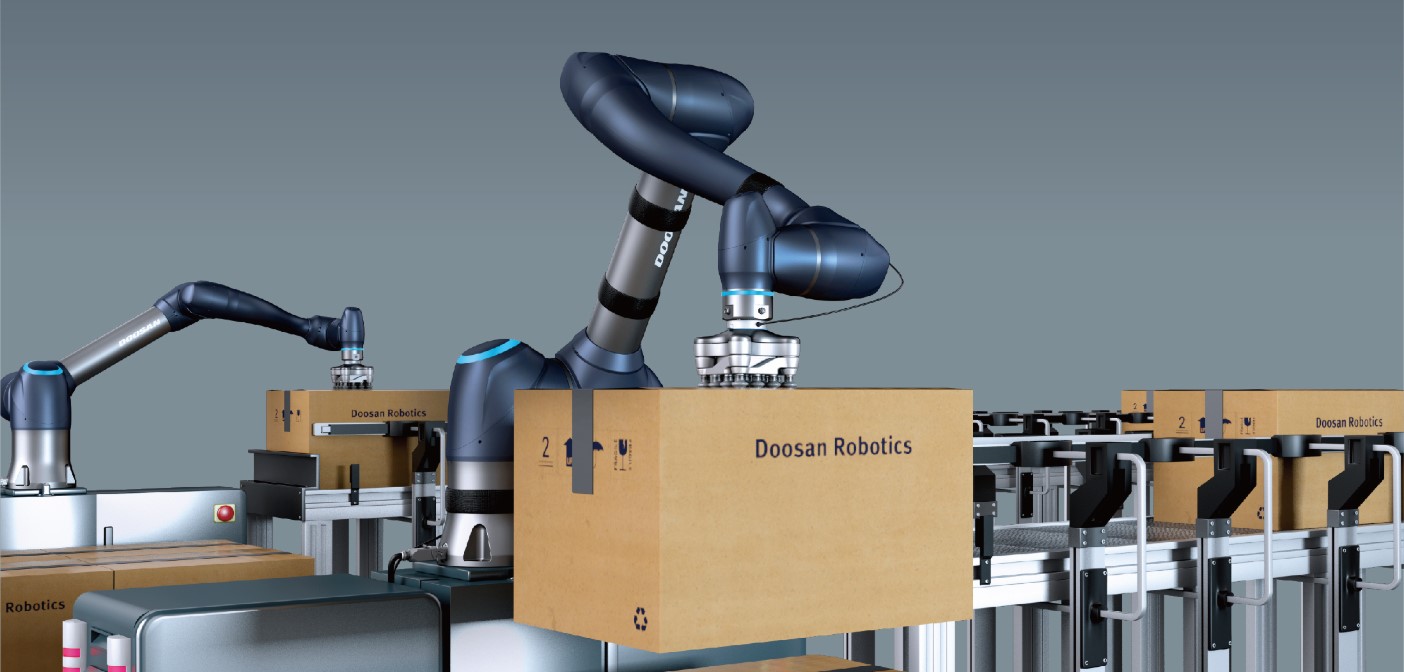

- COBOTS & AGV/AMR

- Worker Guidance

- Exoskeletons & Wearables

- Mutilation Prevention & Safety

- Calibration & Audit

- Material Removal

- MRO

Let Us Prove Our Value

30+

Years of industry experience

200+

Vendor partners for the broadest selection of innovative products via one source

100+

In-house industry specialists to help you throughout the country

Custom Design &

Build Solutions

Unique requirements are our specialty.

If what you need doesn’t already exist, we have the capability to understand your specific need and design, build and deliver a custom product or solution to meet and exceed your requirements.

Industries We Serve

- Automotive & Motor

- Agriculture & Heavy Truck

- Consumer Products

- Medical & Pharmaceutical

- Electrical & Computer

- Energy & Defense

- Aerospace